Grinding and Welding Splatter to Glass

Most damage can be repaired but in most instances grinding damage is a raised molten lump of metal melted in to the glass. It will be Black or has turned rusty.

We can 100% remove all raised and black particles from the surface.

There may be some Small white pin head marks remaining in the glass that is next to un-noticeable and generally meets the AS in glass visibility defect requirements. Wether they can be removed completely is dependent on how close and concentrated the impact was.

We can suggest that in most instances 90% of the marks will be gone and the remaining 10% are those white pin heads.

To read an article on blemishes in glass and to determine if it will need fixing click here: Do I have to fix the scratches in glass?

Glass Grinding Welding Damage – How it happens

Power Tool splatter is caused when using an angle grinder or welder near glass, resulting in burn marks from metal particles appearing on the surface.

Our team can polish and remove all types of grinder and welder splatter damage, restoring the quality of your products.

Removing splatter damage has never been easier or safer, thanks to our fully trained team of technicians.

Call the number above to speak with an expert who will be happy to provide an free quotation.

Severity of splatter damage

Splatter damage can be classified into three main categories depending on the cause: spotted, concentrated and welder.

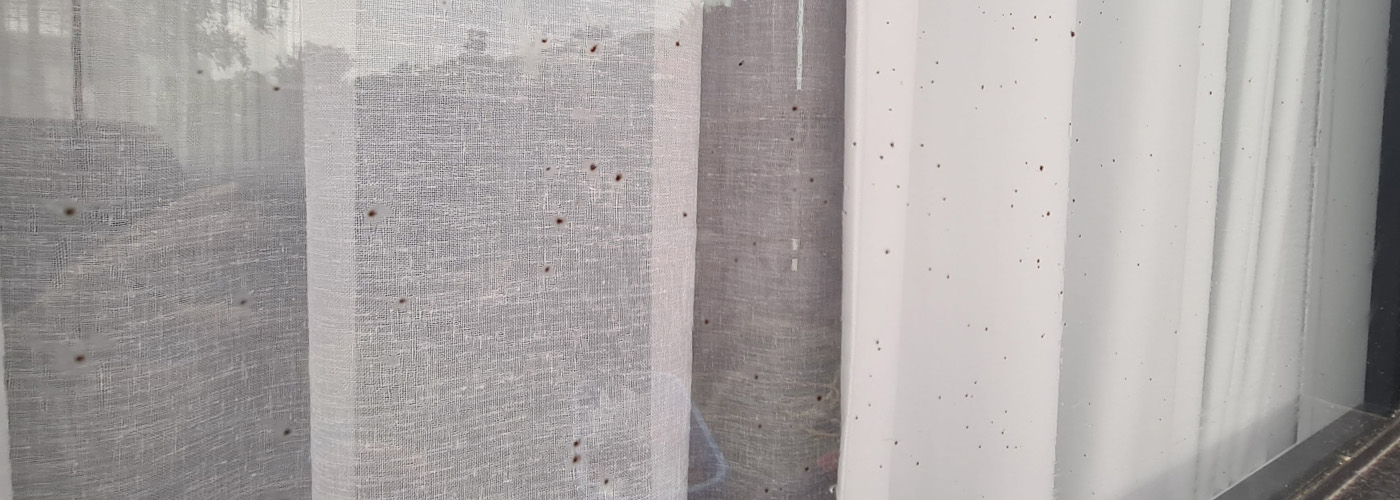

Spotted

Individual burn mark spots spread over the surface. Caused by angle grinders.

Concentrated

Clusters of burn mark spots spread over the surface. Caused by angle grinders.

Welding Slag

Burn marks that look like water drops spread over the surface. Caused by welder splash.

How we fix it?

There is a dual stage repair process for Grinding splatter:

First we remove all metal from the glass. At a minimum this will prevent further rusting of the particles and causing further damage.

Once the dark molten lumps are removed we the restore the glass by abrasively sanding the entire surface are of the damaged glass down below the level of the melted glass.

In some instances where the angle grinder used was in very close proximity and was used very aggressively on the metal the molten steel when it hits the glass explodes in to the surface.

Sometimes this is so aggressive that no amount of sanding is suitable to remove all the damage.

But in most instances there is a Minimum of 90 % reduction in visible damage and will definitely exceed AS4667 for visible quality standards of glass for blemishes.